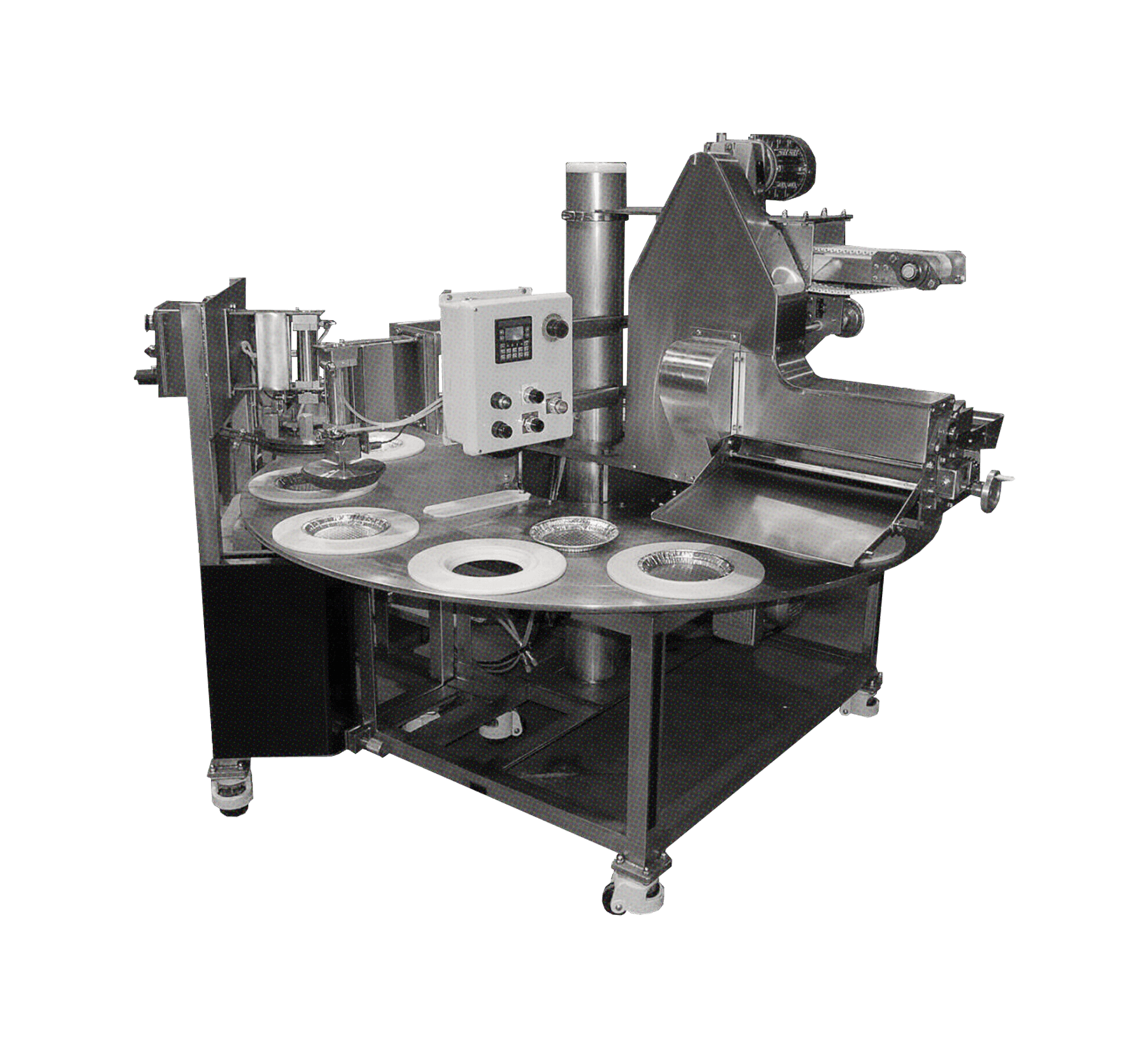

11-Plate

Rotary Pie System

Flaky Pie Crusts

Just Like Handmade

Traditional flaky American pie crusts no longer need to be made by hand. This cross-sheeter makes it automatically.

Artisanal three-direction cross-sheeting

With this method we take an individual block of dough. Sheet it one direction, turn it 90° and sheet in the other direction, then turn it 90° again and sheet it in the other direction. This technique mimics how dough is sheeted by hand, which creates that flaky crust we all know and love. The process is automatic and repetitive, producing the same quality bottom and top crust every time.

Take your pie production from manual to semi-automatic while keeping your product tasting and looking just like homemade!

This is a reliable, corrosion resistant indexing table with variable dwell time allowing adjustment for different stations. This enables you to produce a wide variation of pies including 2-crust pies, single crust filled pies, trimmed shells, high rim shells, pressed shells, graham shells, cream pies (up to two fillings), swirl cheesecake, and garnished topped pies all on the same machine.

Due to it's simple operation, this system allows you to reach maximum potential with minimal training. And the circular configuration uses minimal floor space, allowing installation even in cramped quarters.

Specifications

| Pie Diameter | 3"-12" | |||||

|---|---|---|---|---|---|---|

| Speed Actual Rates Determined |

|

|||||

| Machine Size Actual Size Varies Based |

8' L x 8' W x 6' H | |||||

| Construction |

|

|||||

| Controls |

|

|||||

| Electrical Power Requirements | Wired To Your Plant's Specifications | |||||

| Pneumatic Power Requirements | Approx. 35 CFM @ 100 psi | |||||