Automate your processes and packaging with robots

Consistency and Reliability

Robots can work tirelessly for 24 hours a day, 7 days a week, 365 days a year, with minimal maintenance. Depending on the application automating with a robot can free up two to five, or even more, full time employees. Robotic automation removes human error as most robots are set up to run repetitive tasks with only the necessary movements to complete a given function.

Flexibility and Accuracy

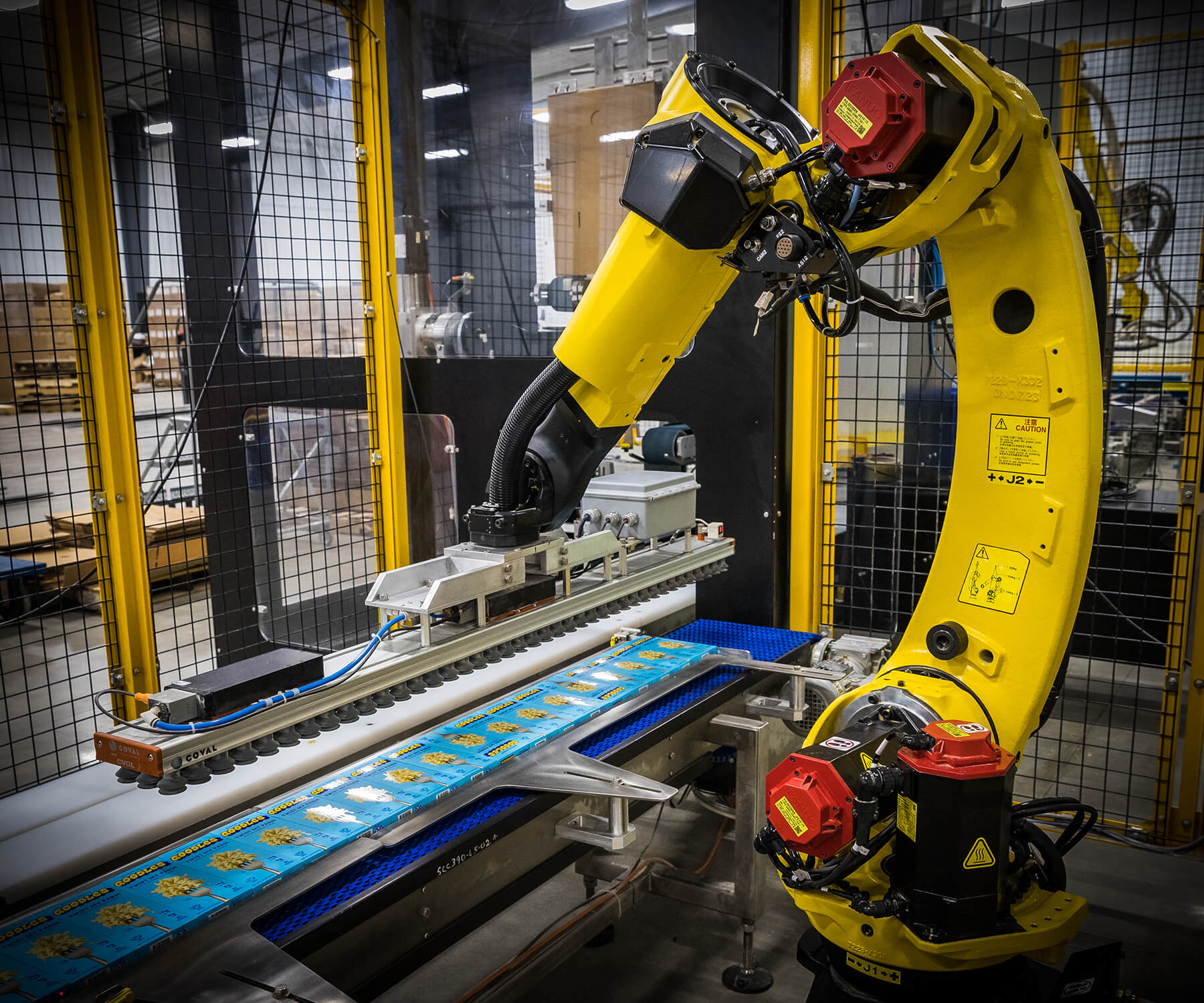

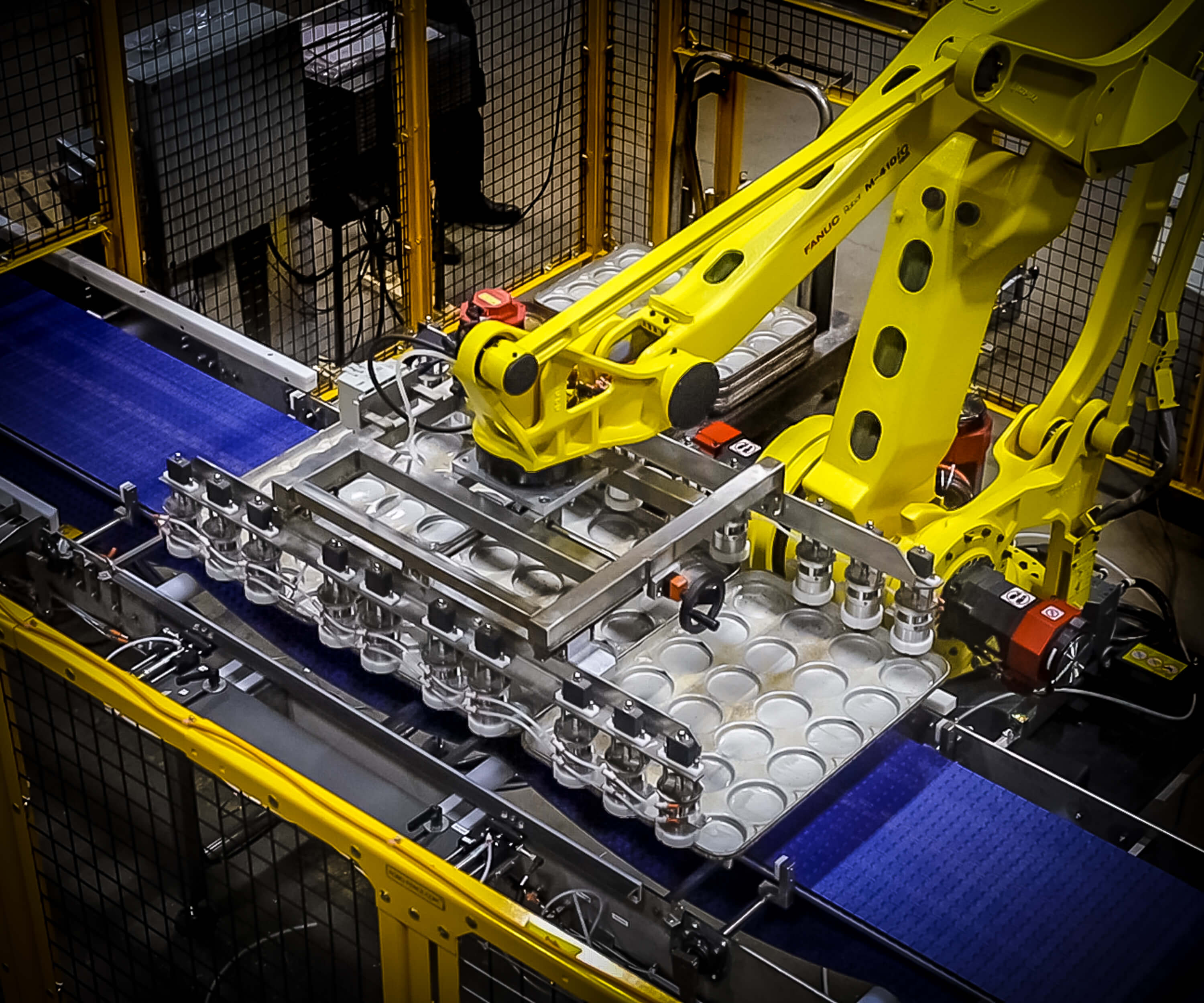

Once a robot is programmed and trained it will perform its functions accurately and consistently all the time. These robots can easily change over with the push of a button. Or when you have a large range of objects you need to handle, custom end of tool arms can be created to handle your products in the most efficient way without damage to your products.

Labor Resources and Utilization

Utilizing robots frees up your skilled personal from mundane tasks so they can be placed in more valuable positions. Workflow can often be unpredictable, but there is no need to take on the added pressure of filling staffing needs. Scaling is easy. Robots can be added when demand is high, or they can be redeployed to handle different tasks.

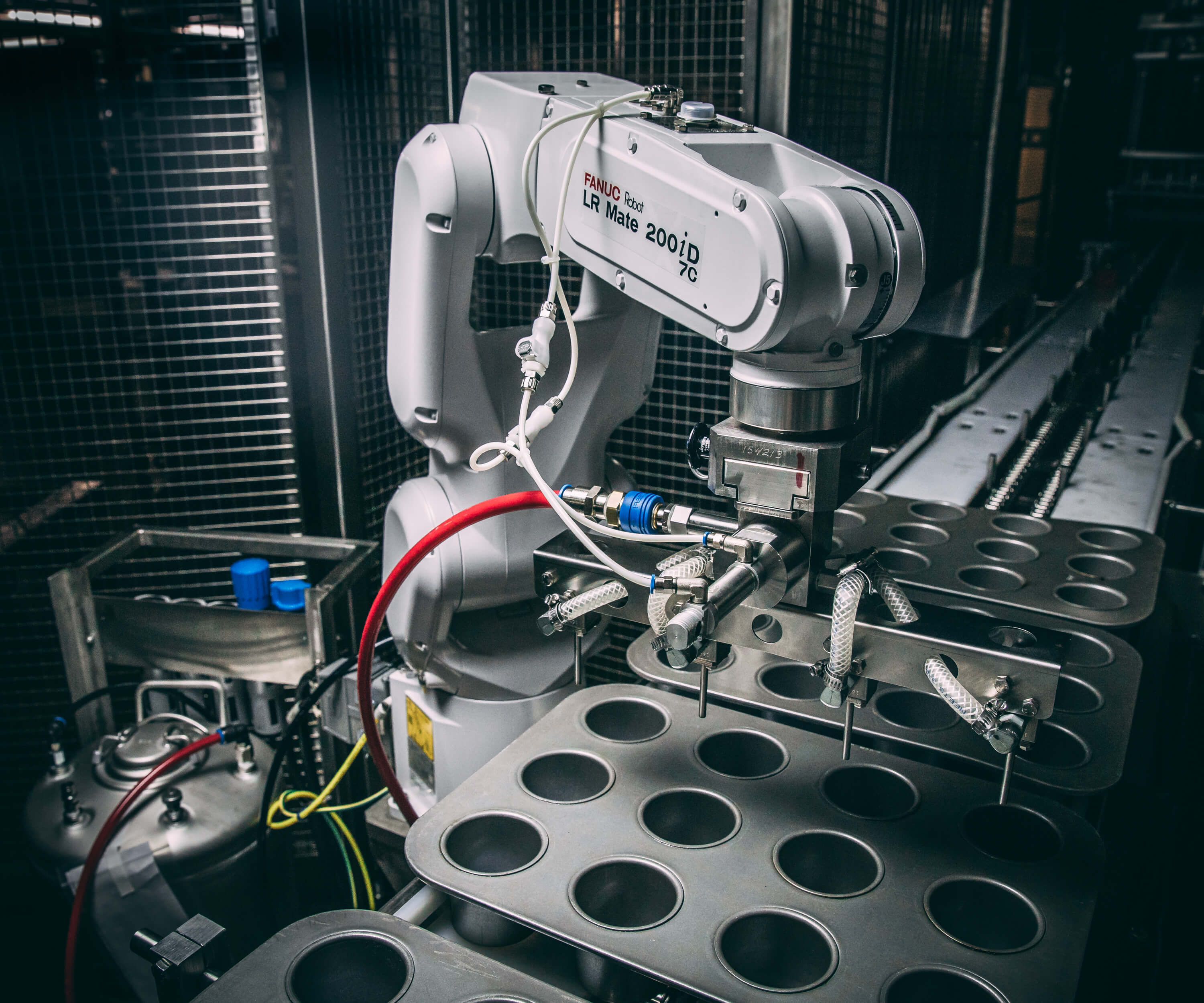

Examples of Work

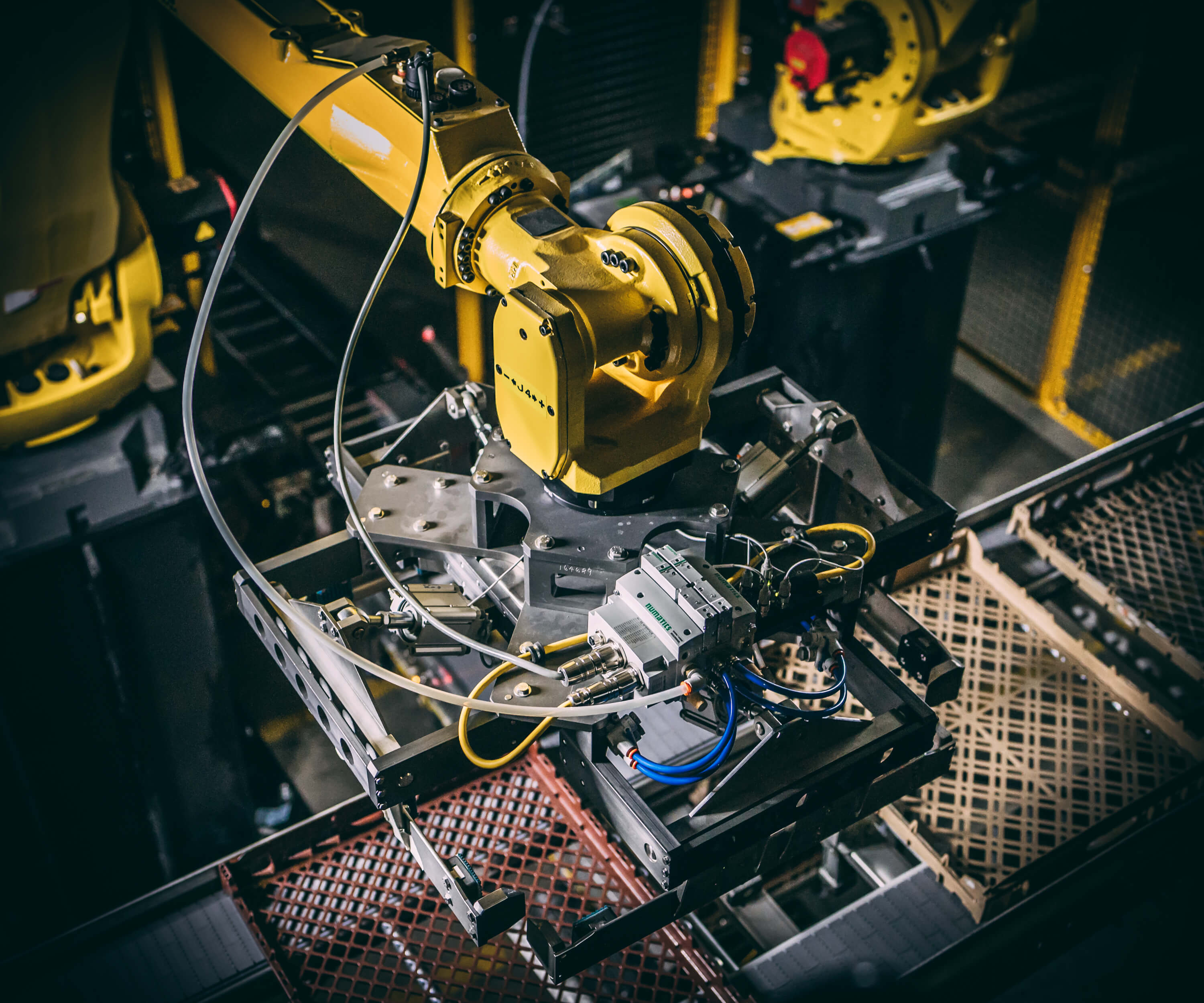

The power of vision

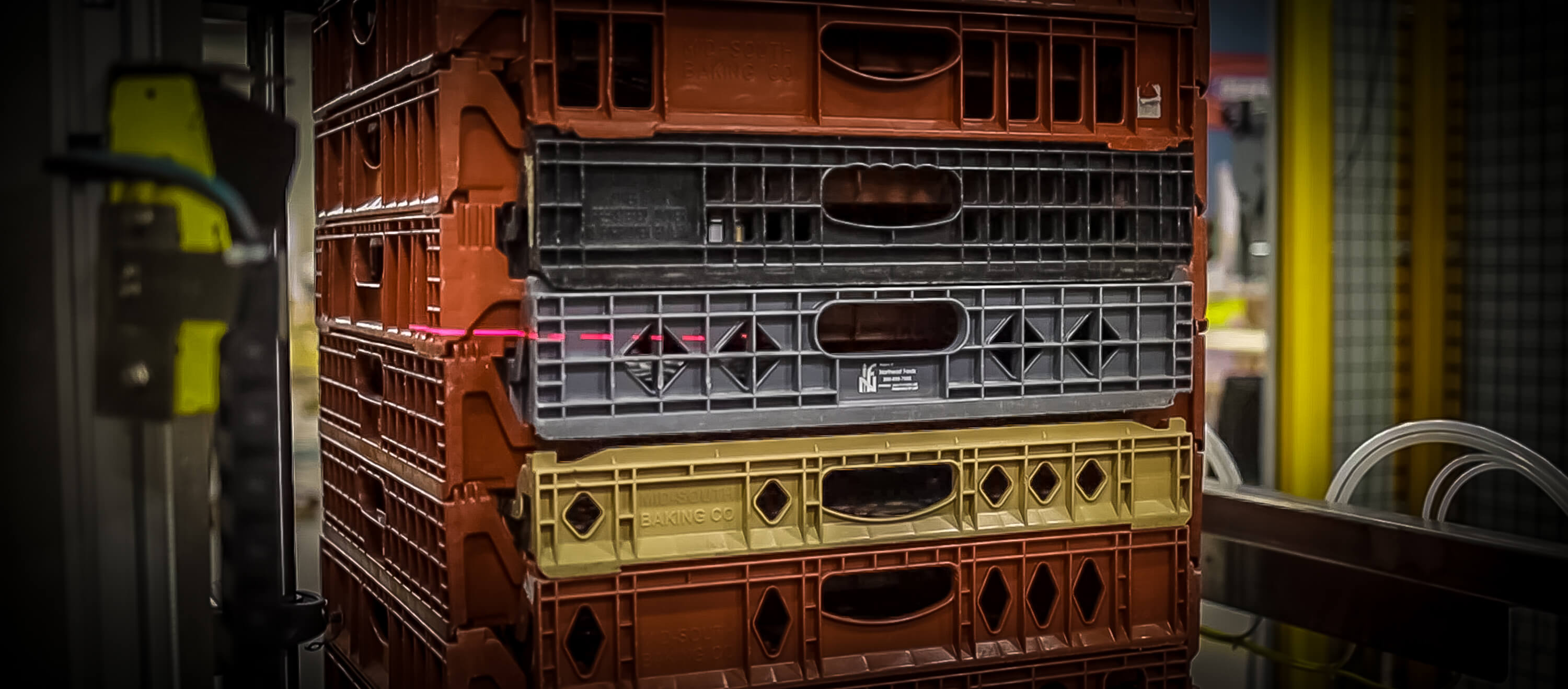

Vision guided robotics (VGR) systems consist of multiple technologies working together to provide reference points for the robot. Using special-purpose lighting, one or more cameras and software, the robots can recognize, process and handle objects based on visual data. Depending on the application this data can be converted into two-dimensional (X and Y) or three-dimensional (X, Y, and Z) information to properly pick, orient, and place objects.

In this example a stack of baskets is conveyed to and waits in front of the VGR system. The stack is scanned for information then the robot separates the baskets based on size and color.